How We Can Help

Understanding the capacity of a plant is fundamental to maximising the value of an asset. Whether that’s increasing plateau rates, maximising late life operation, or understanding the impact of a new field.

Genesis produces debottlenecking assessments that can realise enhanced production capacity in a facility, providing the opportunity to monetise better reservoir performance, introduce new fields or change operating conditions.

How We Can Add Value

Genesis applies a systematic approach that allows rapid identification and focus on the most constrained areas of plant to avoid unnecessary scope.

- Understand the drivers of the client and ask the right questions around hard and soft facility limits to frame the study:

- Which areas of the plant are affected?

- Are design excursions time-limited by production profile?

- Can operating parameters be adjusted to mitigate the impact?

- Are there second-order impact on utilities, services and plant logistics?

- Provide options to optimise and debottleneck / modify parts of the plant including cost estimation.

- Our service is characterised by flexibility and responsiveness, adapting as our clients’ needs change.

- Extensive experience of building complex process simulations and benchmarking of our models against plant operational data has proven time and again to deliver exceptional results.

What Sets Us Apart

A team of process engineers with a depth of experience in performing capacity assessments of varying degrees of complexity. We have proprietary in-house tools available and use these where they complement the engineering assessment:

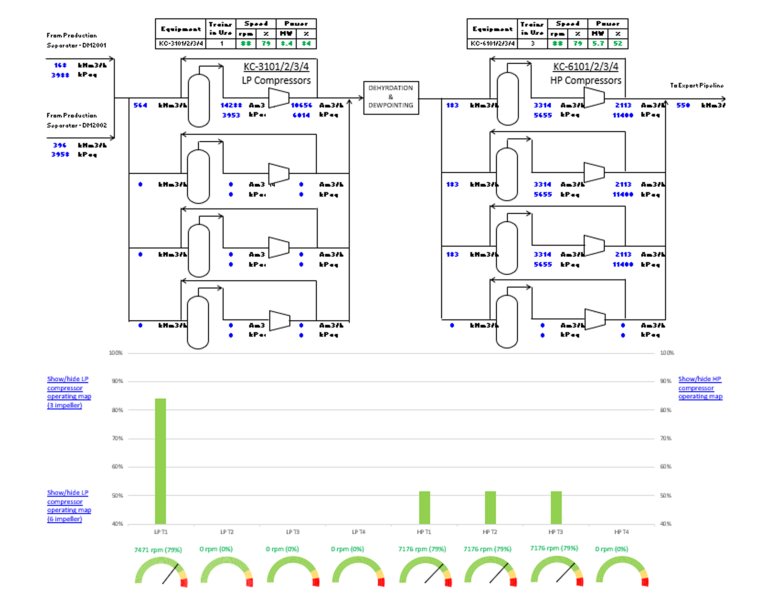

- Bespoke hydraulic models with Graphical User Interface (GUI);

- In-house automated equipment rating tool applying a standardised equipment rating method to a whole plant;

- A range of standardised, proven, design tools for detailed equipment rating.

We have access to a pool of over 200 process engineers and can call on specialists from other engineering disciplines, as needed. We can quickly mobilise a highly capable and cost-efficient study team.

Our Services

Our comprehensive capacity rating services include:

- Steady-state model builds;

- Benchmarking against actual plant performance;

- Determine allowable operating envelopes for required specifications;

- Incorporation of rotating equipment performance curves;

- End to end hydraulics and import/export pipeline hydraulics;

- Assessment of impact on relief devices and systems;

- Thermowell vibration analysis;

- Control valve operational assessment;

- Dynamic Simulation for complicated plants with integrated multistage compression;

- Performance testing support to benchmark / prove enhanced capacity of the plant.

- Continued operations support post debottlenecking

Available Tools and Processes

- Aspen Suite of Software

- Honeywell UniSim Design

- PIPESIM - Steady-state simulation for pipelines

- Excel-based GUI – linked to process modeling software

- In-house equipment sizing tools

- In-house plant capacity rating tool

- Genesis Brownfield cost estimation tool.

- In-house Safe Operating Limits tool.

Get in touch

If you require more information, please contact your local Genesis representative.