OVERVIEW

Project type: A feasibility study

Customer: Confidential

Location: Europe

CHALLENGE

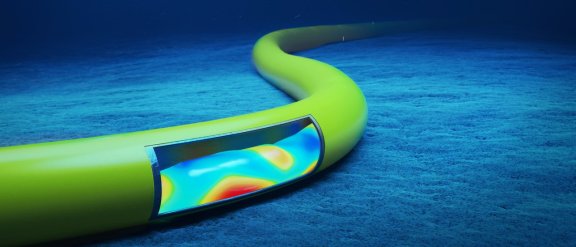

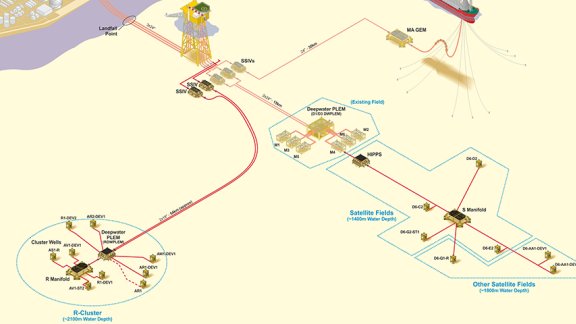

The longer the multiphase pipelines, the more difficulties encountered become exaggerated. Aspects that are mostly accepted over a shorter distance become much more challenging, such as physical property data or even the accuracy of the software can become much more challenging.

During the initial flow assurance analysis, it was identified that the export of untreated multiphase fluid over this distance was not technically feasible, which resulted in a pipeline project "showstopper".

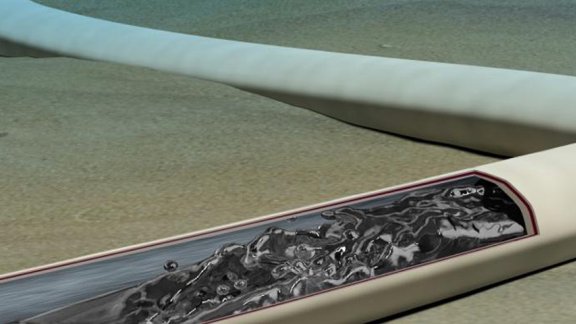

The showstopper, which threatened the project progressing to the next phase, was encountered because of the excessive pressure drop owing to the presence of the aqueous phase. The free water condensed in the pipeline and accumulated until flow ceased as the pressure exceeded its maximum allowable operating pressure.

Of course, we could have increased the pipeline design pressure over this distance but that would challenge the project economics, further exacerbated by the increase in export compression costs.

Our findings identified that the economically attractive way of continuing would be to reduce the water content entering the pipeline.

UNDERSTANDING

Removing the water content before it enters the pipeline provides significant hydraulic benefits which will make a rich gas export feasible. This option benefits pipeline operation since corrosion and hydrate risks associated with a free water phase will no longer be a challenge.

Water removal from the condensate can be achieved using coalescers, couple this with “over” dehydrating the gas ensures that all water entering the pipeline will remain in the gas phase.

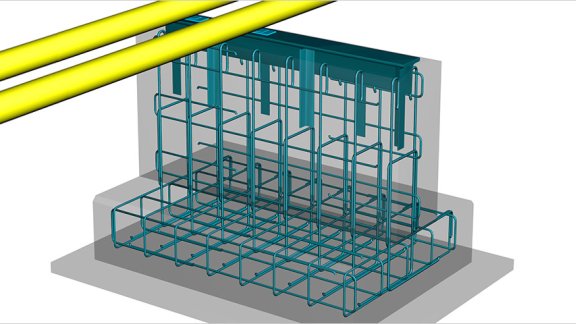

Glycols from TEG (Triethylene Glycol) dehydration and MEG (Monoethylene Glycol) in the condensate can be controlled into the pipeline but do affect the water dewpoint inside the hydrocarbon phase envelope, which results in careful monitoring of the pipeline operating temperature to avoid glycol knock-out.

SOLUTION

A comprehensive cost-benefit analysis using established option identification and screening resulted in a preferred option based on a revisit of scope boundaries and a holistic review of the whole development.

The key decision drivers of the facilities being safe, reliable, and technically feasible that maximises value and appropriately manages project risk ensured a robust technical solution was found to mitigate the flow assurance ‘showstopper’. The concept was developed further by the team as they understood the value to the project of minimising brownfield modifications and a potential onshore plant shut-down. The team identified several areas to capture additional cost savings identified by maximising the use of existing facilities, existing MEG treatment, condensate stabilisation, and savings to the offloading jetty.

RESULTS

Significant CAPEX savings in the order of US$350m were realised and it repositioned the project closer to sanction and resulted in a shorter project schedule.

All projects encounter risk, though certain risks are large enough to stop a project. When this occurs it is often worth engaging with a team of consultants who are experienced in dealing with challenges, such as these, on a daily basis.

This project demonstrates Genesis’ strength in identifying and understanding your project value and delivering strategic area development solutions - risk and value are the opposite sides of the same coin.

Get in touch

If you require more information, please contact your local Genesis representative.